|

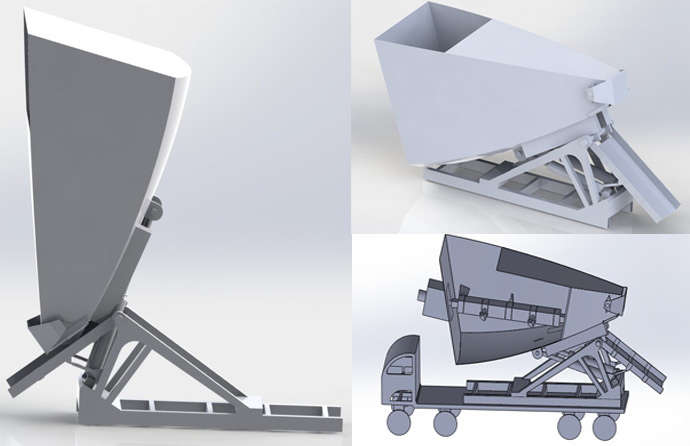

TECHNICAL SPECIFICATION OF TRUCK MOUNTED

AGITATOR |

|

|

1. Truck Mounted Agitator : 6 Cu. Mtr/9 Cu.Mtr/12

Cu. Mtr |

|

Size of the Container (i) 6 Cu.Mtr

Container(ii) 9 Cu.Mtr

Container(iii) 12 Cu. Mtr |

(3500(L) x 2100(W) x 2400(D) mm

(3850 (L) x 2100(W) x 2650 (D) mm

(4100 (L) x 2100 (W) x 2850 (D) mm

|

|

Maximum

aggregate size |

150 mm |

|

Slump |

40 – 150 mm |

|

Thickness of sheet |

8 mm |

|

Thickness of High Wear resistant Polimer |

15mm |

|

No.of Agitator

Arms |

6 Nos |

|

No. of

Agitator Motor |

1 No |

|

Speed of Agitator |

3-6 RPM |

|

Hydraulic Motor |

Danfoss/Sun/Rexroth hydraulics |

|

Approximate Torque Required |

29000 NM |

|

Max.

Torque achieved thru the system offered |

42000 NM |

|

Type of

gang valve provided |

4,3&1Channel valve with Rexroth/

Danfoss /Reputed make. |

|

Load Out

conveyor drive |

OMS 315 Hydraulic

Motor with

variable speed control. |

|

Hydraulic Oil

tank capacity |

Approx. 250 Liters |

|

Hydraulic Cooler |

Thermostat controlled with high

speed fan.

|

|

SPECIAL FEATURES OF THE PRODUCT: |

|

i)

Hi-Buoy promises the efficiency of the Higher

Capacity Concrete Batching Plants to its rated

capacity when placed under plant to receive the

concrete |

|

ii)

High wear resistant Polimer wear tiles provided

inside the container insulates and preserve the

concrete temperature. |

|

iii)

Polimer tiles protects the container surface from

wear and tear. |

|

iv) Polimer

tiles acts as damper to absorb the vibrations induced during

the vehicle in motion and protects the concrete from

segregation.. |

|

v) Agitator

shaft provided inside the drum prevents the setting of

concrete |

|